Briquetting Presses

Briquetting Presses Specification

- Product Type

- Briquetting Presses

- Weight (kg)

- 8500 Kilograms (kg)

- Computerized

- No

- Automatic

- Yes

- PLC Control

- No

- Cooling System

- Air Cooling System

- Voltage

- 440 Volt (v)

- Motor

- AC Motor

- Briquette Size

- 90mm

- MoistureOfMaterial

- MAX 10-12 %

- MaterialLength

- MAX 15mm Millimeter (mm)

- Warranty

- 1 Years

Briquetting Presses Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- EXW

- Payment Terms

- Cheque, Cash in Advance (CID)

- Supply Ability

- 10 Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- TUCK LOAD / 20 FEET CONTAINER

- Main Export Market(s)

- Asia, Central America, South America, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISOQAR

About Briquetting Presses

With More than 25+ Years of extensive domain experience, Radhe engineering Co. mainly engaged in the Research & Development, Manufacturing & Marketing of Renewable Energy Products mainly in Biomass Energy, since 1995.

Radhe Engineering Co, Rajkot are the Manufacturer & Supplier of Renewable Energy Plant & Machinery, specialized in Biomass Related Plant & Machinery.

Our Products Ranges are as under for your ready reference.

Biomass Briquetting (RE 90, RE 70, RE 60)

Biomass Briquetting cum Pellet Machine (90MM Briquette & 16/25MM Pellet Combo)

Biomass Wood Cutter cum Hammer Mill

Biomass Hammer Mill

Biomass Shredder

Biomass Dryer Flash Type

Belt Conveyor Loader

Biomass Briquetting Machine Spares-Ferrous Chips.

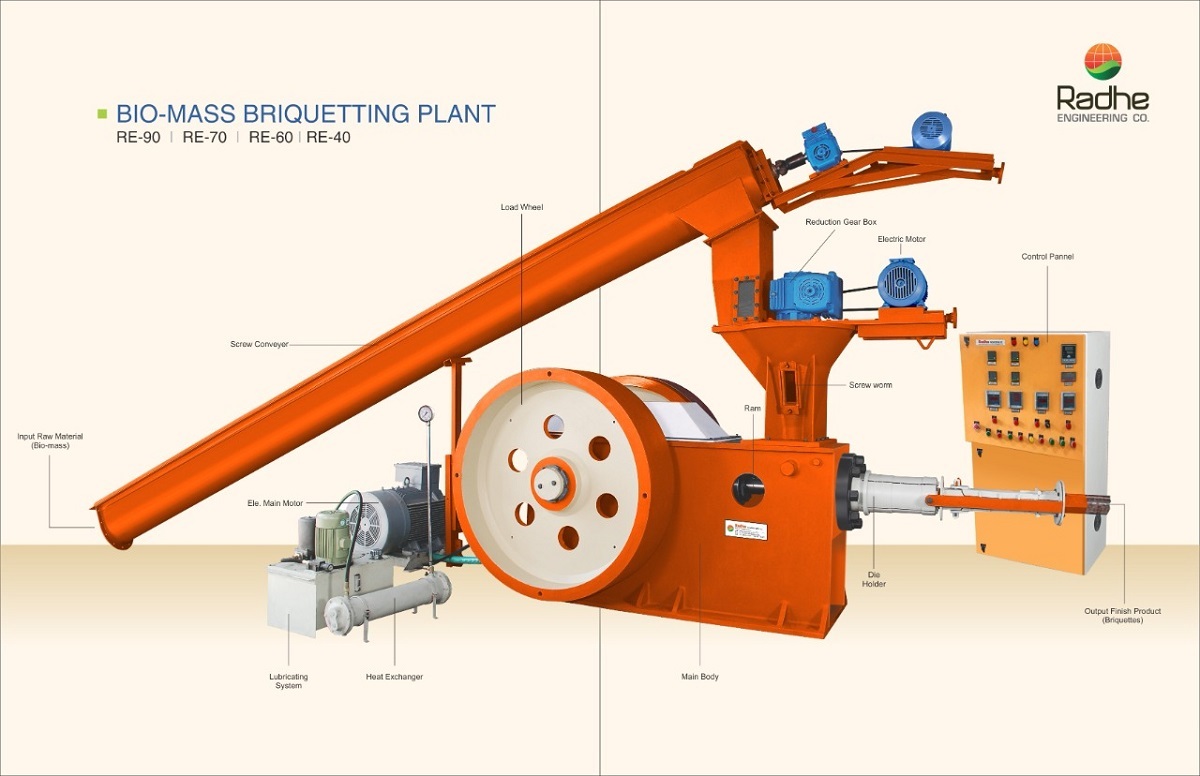

Radhe Engineering Co, Flagship Biomass Briquetting Machine with different capacity are as below:

|

Machine Model |

Capacity/Hr. |

Finished Product Diameter |

Electricity/ Power |

|

|

1 |

Briquetting Machine Jumbo-90 |

1500 kg/ Hr |

90 MM |

Approx. 91 HP |

|

2 |

Briquetting Machine Jumbo-90 with 16mm Pellet |

1000 Kg/Hr |

16 MM |

Approx. 91 Hp |

|

3 |

Briquetting Machine Jumbo-90 with 25mm Pellet |

1200 Kg/Hr |

25 MM |

Approx. 91 Hp |

|

4 |

Briquetting Machine RE-70 |

900 kg/ Hr. |

70 MM |

Approx. 62.5 Hp |

|

5 |

Briquetting Machine RE -60 |

500 kg/ Hr. |

60 MM |

Approx. 49 HP |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Briquetting Machine Category

Industrial Biomass Briquette Machine

Price 2251000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Bituminous Coal

Briquette Size : Standerd

General Use : Agricultural Waste Processing, Biomass Fuel Production

Voltage : 415 Volt (v)

Biomass Briquetting Presses

Price 2251000.0 INR / Number

Minimum Order Quantity : 1 Piece

Product Type : Biomass Briquetting Presses

Briquette Size : 90mm

General Use : Industrial

Voltage : 440 Volt (v)

Send Inquiry

Send Inquiry Call Me Free

Call Me Free